Gripping New Snowmobile Track Technologies

Consider your options in new track technologies

The beauty of snowmobiling centers around its technologies. Sometimes we think change comes slowly, but when we step back and check out what has happened in our favorite sport, we come away amazed at how volatile change has been, especially in this first decade of a new century.

We still find 20th century technology like fan-cooled two-stroke engines powering some 2012 model snowmobiles. But in this first decade-plus of the 21st century, we barely give a passing thought to the fact that modern sleds have become sporty and powerful with sophisticated motors dynamically tuned with a full complement of electronics, computerization, multi-valved cylinder heads, radically tuned intakes and pressure valve exhausts that build low end torque and top speed power from the same exhaust pipes. The dramatic shift in how we ride our sleds of this century is commonplace now. We sit forward, almost directly over the engine, no longer far back over the rear axle. Modern suspensions interact from front to rear via externally mounted appendages, some controlled electronically via a handlebar-mounted thumb control. We’ve come a long way from bogie wheels and 3-inches of foam in the seats.

Like the snowmobile, the snowmobile track is expected to perform flawlessly in virtually all trail and off-trail conditions.

Like the snowmobile, the snowmobile track is expected to perform flawlessly in virtually all trail and off-trail conditions.As we head into the second decade of the new century, we look under the sled to witness serious changes to the sled’s track. Back in the day, track technology consisted of rubber or poly fabrics with full width or two-third width steel cleated grippers, only slowly moving to today’s commonly accepted all rubber designs with internal fiberglass bracing. That’s quickly changing as Camoplast, one of the world’s premiere track suppliers, brings us a plethora of snow gripping tracks incorporating some very clever technology.

It used to be that Ski-Doo riders fought bar stool battles in trailside taverns with Arctic Cat and other cleated track riders. Besides defending the honor of the brand, these battling riders would debate the merits of a rubber track (Ski-Doo) versus a cleated track (Arctic Cat and many others). Eventually rubber tracks became the accepted choice, more or less. But, now the battle may re-emerge, not as rubber versus cleated, but as what kind of rubber track — a Cobra, HackSaw or RipSaw design. And that’s just the half of it as Camoplast has essentially impregnated some rubber best sellers with clever and innovative metal cleats for extra on-ice grip. And that involves formulating various degrees of flexibility into the rubber profiles, something powder riders have known for a few seasons now.

Meaningful Designs

What has Camoplast brought to the world of snowmobiling? While it’s not like the choices you have when you pull into a Canadian Tire or Goodyear Tire store with your pickup, the options for on and off trail traction for your sled are about as meaningful.

A sled’s track is expected to grip loose powder, hold the sled around corners and last indefinitely.

A sled’s track is expected to grip loose powder, hold the sled around corners and last indefinitely.Camoplast offers track designs for virtually every type of rider and virtually every riding choice. It doesn’t matter if you are a high performance, hot rod trail rider or a high mileage touring rider, there are meaningful options for all. As the sport has evolved, riders look for performance advantages. High performance riders want grip for acceleration and cornering. Boondocker riders want grip for the trail but extra lug height to power through ungroomed snow when they go off trail. High mile touring riders want a long lasting track that can spin reliably mile after mile, weekend after weekend. To one degree or another the sled makers have arrived at the best track designs to suit each of their models. However, today’s ever-savvy riders want more options to suit their sledding life style.

Camoplast designed subgroups within the larger context of basic tracks. As the company notes: “Any snowmobiler can improve the performance and safety of their machine with a new track. It is simply the most sensible and often the most cost-effective modification possible.”

Performance tracks have become specialized to match the way you ride. It is essential when you consider a performance upgrade that you examine what you really want to accomplish as no one track can be the best at everything. For example, while an aggressive track with more tall lugs will provide a better bite and give you better acceleration and braking, those same taller lugs also increase weight and aerodynamic losses. These factors work against the track at higher speeds, meaning that top speed will be decreased compared to shorter lug tracks.

If you like hanging a sled’s tail out in corners, consider that some tracks provide exceptional lateral bite for stability and cornering, but can limit your fun of sliding the rear end through the corners.

Seriously think about where you ride, how you ride, and what you want a track to do better before choosing a track upgrade. Fortunately, Camoplast offers many different performance track options.

Performance Options

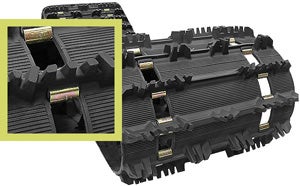

One of the most popular tracks among performance riders, the RipSaw features an unique traction profile. (Image courtesy of Camoplast)

One of the most popular tracks among performance riders, the RipSaw features an unique traction profile. (Image courtesy of Camoplast)Even between sled models you’ll find track options. One of the most common is the RipSaw, which is now one of the most popular tracks offered on performance models.

If you want to upgrade a late model performance sled, there are two good choices: Camoplast’s RipSaw or Cobra tracks. Both provide a performance boost, but there are real differences between them.

The extremely popular RipSaw uses a very aggressive track design with angled track lug profiles for superior straight ahead traction for acceleration and braking. It also offers lateral bite for predictable and precision handling in a wide variety of snow conditions. The design features a narrow lug base and slotted design that reduces rolling resistance for more efficient use of the sled’s horsepower. Hard rubber outside edges allow for increased durability and traction. Since this design is available in a wide variety of sizes and can be easily studded, the RipSaw has settled in as a benchmark for trail performance tracks.

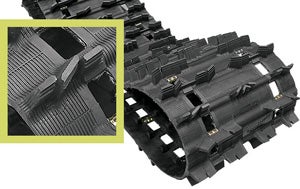

The Cobra track with its innovative lightweight lug design continues the evolution of the RipSaw. (Image courtesy of Camoplast)

The Cobra track with its innovative lightweight lug design continues the evolution of the RipSaw. (Image courtesy of Camoplast)Camoplast’s Cobra track actually represents the next generation design of high-performance track for trail sleds. With its innovative lightweight lug design, the Cobra is engineered with an extended cutting edge for improved bite on hard pack. The unique construction and the cupped lugs give you excellent traction and performance in loose snow without sacrificing top end. Versus the RipSaw, the Cobra should give you improved acceleration with comparable top speeds. Plus, for you riders that like to hang it out in the corners, the Cobra gives you the fun of slipping the tail out while still maintaining control and forward traction on the trail.

That’s all well and good for hot rodding with a short tracked sled, but what about venturing off-trail with a crossover model? You have some nifty options, too.

Off-trail riding means anything from jumping off groomed routes to trailside play areas to running an ungroomed fire road or venturing into serious backcountry. The fundamental needs of an off-trail rider center on a tough track that will give you extra traction when the terrain gets tough and the snow gets deep.

Crossover riders look for a taller lug and stiffer track construction to counter deep snow and off-trail debris. (Image courtesy of Camoplast)

Crossover riders look for a taller lug and stiffer track construction to counter deep snow and off-trail debris. (Image courtesy of Camoplast)To get the right track for your off-trail needs, honestly consider how and where you ride off-trail. For example, how much time do you really spend on hard packed trails getting to and from your off-trail ride sites? A mid-height 1.5-inch lug is a good compromise for riders who split time between their on and off trail riding adventures. However, if you determine that you spend most of your time off trail, you’ll want a more aggressive track, such as one with a 1.75-inch lug profile.

Camoplast offers a variety of off-trail options, including its new BackCountry model, which was derived from snocross racing and constructed with flat-faced lug designs for maximum forward thrust in deep, mealy snow conditions. Camoplast’s Intense, Crossover, and RipSaw 1.5 and RipSaw 1.75 models feature various multi-element lug designs engineered to help control side slip for better handling on or off the trail.

ICE Technology

If you want superior grip, you’d normally obtain a track and add any combination of studs or picks. One of the most evolved options for modern snowmobilers is represented by Camoplast’s Ice Control Enhancement (ICE) series of tracks. The ICE technology track blends current track designs with a revolutionary way of adding steel ice grippers,

As we’ve noted, sled tracks have evolved due to new materials and construction methods to give us ever improved groomed trail traction and off-trail snow-ability. We are far more in control than we ever were in the good old days. Still, for the maximum of control in the corners or when emergency braking, there is nothing that truly compares to a studded track, especially on icy trails.

In the past season or two, we’ve begun to see what we believe will be an ever growing trend as all manufacturers will over the latest track engineering breakthrough from Camoplast, the ICE track. Some sled makers offer these tracks as options. What they represent is: “…the industry’s only turnkey solution to performance and safety improvements for icy conditions. They provide the benefits of studding without the drawbacks.”

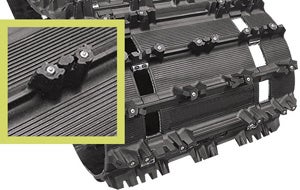

Based on the very popular RipSaw track, Camoplast’s Ice Ripper XT is pre-studded at the factory with dozens of small, sharp-tip lug studs. (Image courtesy of Camoplast)

Based on the very popular RipSaw track, Camoplast’s Ice Ripper XT is pre-studded at the factory with dozens of small, sharp-tip lug studs. (Image courtesy of Camoplast)ICE technology tracks are pre-studded at the factory with dozens of small, sharp-tip lug studs. This proprietary technology not only improves acceleration, braking, and handling on ice and hard pack but, amazingly, adds less than one pound to the overall weight of the track. Since the tracks are pre-studded into Camoplast’s ICE Tech lugs, there is no installation or post-installation maintenance. The ICE Tech track costs less than a new standard track with conventional studs and is backed by Camoplast warranty protection.

Camoplast ICE Technology tracks are available in a variety of sizes, lug patterns, and lug heights for most popular trail and utility sled applications. Currently there are two main pre-studded designs, the ICE Attak, which is derived from the popular Hacksaw design and the Ice Ripper XT, based on the RipSaw track. We envision that the RipSaw-based Ice Ripper XT will quickly prove to be the more popular design.

When it comes to handling icy trails, little works as well as steel track studs. And Camoplast has completely revolutionized studding with Ice Control Enhancement (ICE) tracks.

If you are a more traditional rider and favor your own studding options, Camoplast offers “pre-holed” tracks, specifically engineered to handle the added stresses of conventional track studs. These TRACKtion Control System tracks were co-developed with a leading track stud manufacturer. This track option offers a pre-drilled layout for easy stud installation.

In this era of modern snowmobile traction, there is an ever-expanding list of options that we’ve never enjoyed before. While we enjoyed the golden days of vintage riding of “back in the day”, we greatly prefer the modern era with its reliability, durability, and evolved options. For us, this is the golden age of the sport.

Related Reading How to Install an Aftermarket Track On Track Camoplast Cobra Track Review Track Studding the Right Way

Your Privacy Choices

Your Privacy Choices